The journey from conceptualization to a tangible object is often a long one. For designers utilizing powerful 3D modeling software like SolidWorks, the transition into the physical realm frequently necessitates the precision and capabilities of CNC machining. CNC (Computer Numerical Control) machines, guided by intricate code generated derived from 3D models, transform raw materials into precise components with remarkable accuracy.

This symbiotic relationship between SolidWorks and CNC has revolutionized the design industry.

- Designs created in SolidWorks can be readily exported as G-code, the language understood by CNC machines.

- Automated fabrication offers exceptional control over dimensions, ensuring intricate details are faithfully reproduced.

- Utilizing prototypes to high-volume production runs, the SolidWorks-to-CNC workflow provides a versatile solution for a wide range of applications.

Mastering CNC Machining with Precision 3D Printed Parts

The convergence of CNC machining and 3D printing technologies presents a paradigm shift manufacturing processes. By leveraging the finesse of 3D printed parts, machinists can fabricate intricate components with unparalleled detail. This alliance unlocks a realm of possibilities for manufacturers, enabling them to break the limits of traditional machining techniques.

CNC machining, with its inherent ability for high-volume production and strength, complements the adaptability of 3D printing. This combination allows manufacturers to optimize their workflows by combining additive and subtractive manufacturing processes. The result is a harmonious approach that yields superior performance.

- Employing 3D-printed tooling for CNC machining

- Producing highly customized parts using 3D printing

- Optimizing manufacturing timelines

Embark on SolidWorks for Beginners: Designing Your First Printable 3D Model

Ready to kick off your journey into the world of 3D design? SolidWorks, a powerful and versatile CAD tool, empowers you to craft your ideas to life. With its intuitive interface and robust features, even beginners can navigate this popular design application. In this article, we'll guide you through the essential steps of creating your first printable 3D model in SolidWorks. Get ready to discover your creative potential and mold your imagination into tangible objects.

Let's begin by familiarizing ourselves with the basic tools and ideas of SolidWorks. We'll explore how to sketch 2D profiles, extrude them into 3D shapes, and manipulate their dimensions. As you progress, we'll delve into more advanced techniques such as incorporating features, creating fillets and chamfers, and producing your final design ready here for 3D printing.

- Throughout this tutorial, we'll provide you with clear guides and helpful illustrations. Don't be afraid to play and push your creative boundaries.

- Keep in mind that practice is key to mastering any new skill. So, dive in and start designing your first printable 3D model in SolidWorks today!

CNC Milling vs. Fused Deposition Modeling: Choosing the Right Method for Your Project

When faced with a new project requiring physical fabrication, selecting the appropriate method can be a daunting task. Two popular options stand out: CNC milling and 3D printing. Both offer unique advantages and limitations, making the choice dependent on design parameters.

CNC milling utilizes rotating cutting tools to carve designs from a solid block of material. This process excels at producing highly precise parts with smooth faces. However, it's typically limited to dense substances and can be less adaptive for complex geometries.

Alternatively, 3D printing builds objects layer by layer from a digital model. This additive process allows for unprecedented design freedom, enabling the creation of intricate forms and customized parts. While rapid prototyping is a hallmark of 3D printing, it currently faces limitations in material selection and achievable strength.

Therefore, the optimal choice hinges on several factors. For projects demanding high accuracy, complex shapes within limited materials, CNC milling often reigns supreme. Conversely, if customization takes precedence, 3D printing emerges as a compelling solution. Carefully considering these aspects will ensure you select the method best suited to your project's unique objectives.

Tuning 3D Models for Both SolidWorks and CNC Machining

Creating efficient 3D models that seamlessly transition from Solidworks to the CNC machining process requires careful consideration. The specifications of your model must be precisely outlined to ensure accurate fabrication. When transferring your 3D model for CNC machining, it's crucial to select the correct file format, often STL or STEP, which are widely supported by CNC software.

Furthermore, reducing unnecessary details in your model can improve both design performance and machining time. Always confirm the accuracy of your model's measurements to avoid potential errors during production.

Advanced Techniques in SolidWorks for Complex 3D Printing Projects

SolidWorks provides a robust suite of tools for engineers and designers to develop intricate 3D models. When it comes to complex printing projects, these tools become vital. Mastering advanced techniques within SolidWorks can significantly optimize the design process, leading to more efficient outcomes.

One key technique is dynamic modeling. This allows designers to create models with interrelated features, enabling easy modifications and adjustments throughout the design process. Another powerful tool is simulation, which permits engineers to analyze the mechanical integrity of their designs before physical printing.

Additionally, SolidWorks offers a wide range of add-ins and plugins that can extend its functionality for 3D printing. These can automate tasks such as slicing, support generation, and manufacturing preparation.

By leveraging these advanced techniques, designers and engineers can push the boundaries of 3D printing, creating complex and cutting-edge products that were previously unachievable.

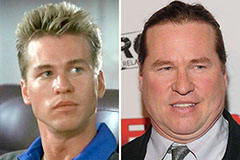

Val Kilmer Then & Now!

Val Kilmer Then & Now! Destiny’s Child Then & Now!

Destiny’s Child Then & Now! Jennifer Love Hewitt Then & Now!

Jennifer Love Hewitt Then & Now! Danica McKellar Then & Now!

Danica McKellar Then & Now! Ricky Schroder Then & Now!

Ricky Schroder Then & Now!